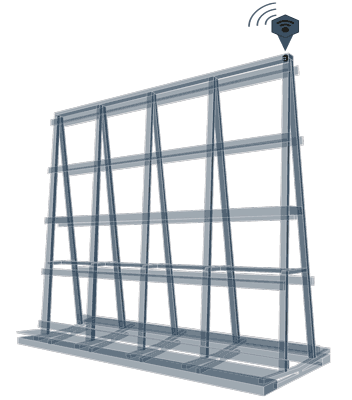

Extensive sensor technology

- Collecting position and movement data

- Confirmation of Delivery and Glass Damage

- Attached documentation and images

- Long battery life / low operating costs

0G Network from Heliot

- More than 12 years of experience in IoT implementation

- Network operation: planning, set-up, monitoring and maintenance

- Available in over 70 countries

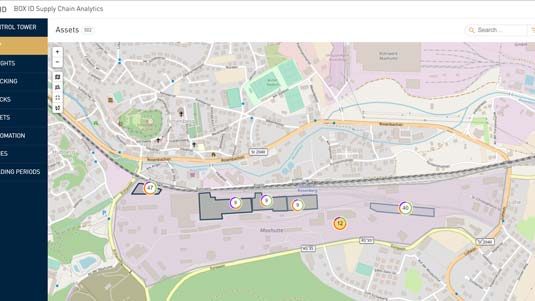

Software platform

- Designed for supply chain optimisation

- Tracking the location history

- Detailed insights into reports - Holding / idle times

- Automated inventory

- Assets overview